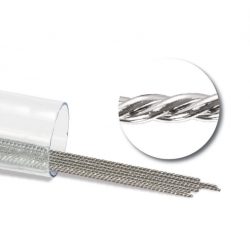

Stainless Steel Archwires

Stainless Steel Orthodontic Archwires for Working and Finishing

In this subcategory, you’ll find stainless steel archwires for bracket systems - working and finishing, round and rectangular, in the most commonly used sizes. Stainless steel orthodontic archwires remain a key tool for stages where the clinician needs maximum control over tooth position, torque, and rotation. This is where you can build your inventory of stainless steel archwires for braces according to your clinical protocols and practice standards without sifting through the entire catalog manually.

The role of stainless steel orthodontic archwires in treatment

Stainless steel is the material of choice when the “gentle” force of NiTi is no longer enough and you need rigidity, stability, and precise bend expression. Orthodontic stainless steel archwires are used in both working and finishing stages, when you need to refine occlusion, stabilize the achieved result, and implement more complex biomechanics.

Steel archwires for orthodontics allow you to control root position, occlusal plane, and the fine details that define the final esthetic and functional outcome. Stainless steel behaves predictably under load, holds its shape well, and transfers exactly the bends you place into the wire.

Key properties and advantages of stainless steel archwires

The main advantage of stainless steel archwires is their rigidity and form stability. Unlike NiTi and TMA, stainless steel wires have minimal “spring” and act as a rigid framework for final tooth positioning.

Torque and rotation control

Most of the advanced bends and fine adjustments are carried out on steel. Stainless steel archwires for torque control allow you to fully express bracket prescriptions and refine root inclination and tooth position.

In the finishing phase, stainless steel archwires for detailing give you the ability to correct minor discrepancies, adjust contacts, refine the smile arc, and fine-tune occlusion while relying on a stable, non-flexing wire.

Rigidity and shape stability

Stainless steel archwires tolerate long-term wear, maintain the intended shape, and are less prone to deformation under load. This gives you predictable mechanics: you know how the wire will behave from visit to visit and can plan adjustments more accurately. Steel archwires for orthodontics are a working tool for phases where precision and control are more important than ultra-gentle forces.

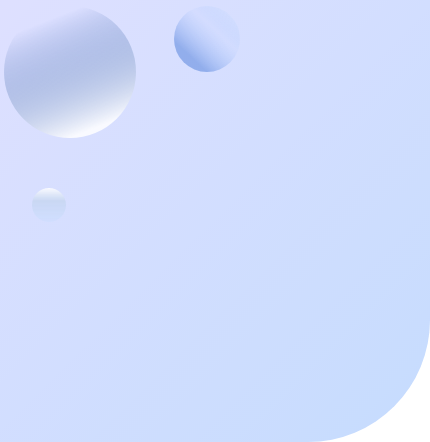

Shapes and cross-sections of stainless steel archwires

Stainless steel is used in both round and rectangular cross-sections - each format has its own role at specific stages of treatment.

Round stainless steel archwires for stabilization and auxiliary mechanics

Round stainless steel archwires are used where you need a rigid framework without full torque control: segment stabilization, auxiliary wires, anchorage constructs, or support when working with springs and other auxiliaries.

Round stainless steel wires are often used after NiTi and TMA when you need to lock in the achieved alignment without immediately moving to rectangular sections.

Rectangular stainless steel archwires for finishing and full control

The main tool for finishing is rectangular stainless steel archwires. These wires fill the bracket slot more completely and allow you to fully express all bracket and wire prescriptions.

Stainless steel working archwires are used in working stages when you need a balance between rigidity and the ability to individualize the wire for each case. Stainless steel finishing archwires are the final wires you use to detail occlusion and bring tooth position to the desired parameters.

Common stainless steel archwire sizes

In daily practice, the most frequently used sizes include: 0.016 stainless steel archwire and 0.018 stainless steel archwire for basic stabilization and transition phases, as well as 0.017×0.025 stainless steel archwire and 0.019×0.025 stainless steel archwire for full torque control and finishing detail.

The exact combination depends on your protocols and bracket systems, but these sizes form the core set for most practices.

How to integrate stainless steel archwires into your clinical protocol

A typical treatment sequence looks like NiTi → TMA → stainless steel. Initially you use NiTi for gentle alignment, then beta titanium (TMA) archwires for more controlled but still relatively light forces, and finally move to stainless steel orthodontic archwires when maximum control is required.

Stainless steel is most appropriate:

- in working stages when you need precise bend expression and rotation control;

- in finishing stages when you are detailing occlusion;

- in complex clinical cases where rigid mechanics are essential.

It’s important for every clinic to maintain a stock of stainless steel working archwires and stainless steel finishing archwires in key sizes so that you never have to delay the transition to stainless steel simply because the right wire is not available.

Convenient stainless steel archwire ordering at Orthazone

A practical advantage for clinicians and purchasers is how Orthazone structures its catalog. In the stainless steel section, you can not only select the orthodontic stainless steel archwires you need, but also easily combine your order with other categories such as NiTi archwires, TMA wires, organizers, springs, bracket systems, and bonding supplies.

Orthazone works with multiple brands and suppliers, but you don’t have to place several separate orders: you build one cart, receive everything in one shipment, and pay for shipping once without extra logistical costs. This is especially convenient for practices that order archwires, bracket systems, bonding materials, and elastomeric products together.

Stainless steel archwires for sale and supplies for US clinics

This category is designed for orthodontic offices that actively use stainless steel at working and finishing stages. Here you’ll find stainless steel archwires for sale in formats suitable for single-chair practices and busy multi-chair clinics alike.

We build the range so that stainless steel orthodontic archwire supplies USA meet key needs: popular sizes and cross-sections, stable stock availability, and the ability to quickly replenish inventory without changing proven protocols.

Buy stainless steel archwires online at Orthazone

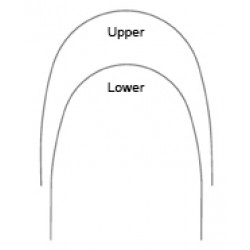

Ordering stainless steel archwires online simplifies work for both the doctor and the assistant. In the Stainless Steel Archwires section, you can buy stainless steel archwires online in just a few steps: select archform (upper/lower), cross-section (round or rectangular), size, and manufacturer.

The system makes it easy to repeat previous orders and create templates for your standard treatment schemes. For practices that regularly restock stainless steel orthodontic archwire supplies USA, this reduces the risk of “we don’t have the finishing wire we need today” scenarios.

Stainless steel archwires wholesale for multi-chair practices

For multi-chair and group practices, stainless steel archwires wholesale purchasing is especially relevant – ordering in bulk according to standard protocols and expected case volume. This lets you cover your needs in advance and reduce the number of small, urgent reorders.

Wholesale stainless steel orthodontic archwire supplies USA help you:

- reduce per-unit cost through volume purchasing;

- ensure stable availability of key sizes;

- standardize stainless steel archwire sets for the entire clinical team;

- streamline budgeting for consumable orthodontic materials.

FAQ: choosing and using stainless steel archwires

When should I switch from NiTi/TMA to stainless steel?

In most cases, you transition to stainless steel after NiTi and TMA have completed alignment and preliminary control. Once your main goals become detailing, torque control, and stabilization, stainless steel orthodontic archwires are the logical next step.

How do round and rectangular stainless steel archwires differ in clinical use?

Round stainless steel archwires are used more often for stabilization and auxiliary tasks when full torque control is not the priority. Rectangular stainless steel archwires are designed for working and finishing stages, providing maximum control over tooth and root position.

Which stainless steel archwire sizes should I keep in a core set?

Most practices include 0.016 and 0.018 stainless steel archwire sizes for intermediate and stabilizing tasks, plus 0.017×0.025 and 0.019×0.025 stainless steel archwire sizes for torque control and finishing detail. The exact set depends on your protocols, but these sizes are universally useful.

Can stainless steel archwires be used at every stage of treatment?

Technically yes, but in practice the most comfortable and physiologic approach is a sequence of NiTi → TMA → stainless steel. Stainless steel is optimal where precision and control matter most, and this is exactly where orthodontic stainless steel archwires show their full strength.

Supplier: Smile Stream Solutions, Inc.

Supplier: Dentaurum Inc.

Supplier: Dentaurum Inc.

Supplier: Dentaurum Inc.

Supplier: Sky Dental Supply Inc.

Supplier: Dentaurum Inc.

Supplier: Dentaurum Inc.

-250x250.jpg)

-250x250.jpg)

-250x250.jpg)